My visit to Makani Power, May 4, 2012

Photo credit: Jonathan Koomey

I like site visits—there’s nothing like seeing a company’s innovations in person. In the case of Makani Power, I harbored some core misconceptions about their technology, and the visit set me straight.

Corwin Hardham, CEO and one of the co-founders of Makani, invited me to visit in Fall 2011. An intern of his was taking the class I taught that semester, and he heard me mention the company’s efforts in lecture, so he put Corwin in touch with me. Things have been so busy that I wasn’t able to arrange a visit until a few weeks ago, but I’m sure glad I stopped by.

When I drove up to Makani’s building, which formerly housed the control tower for the Alameda Naval Air Station, the first thing I saw was three rusted artillery guns. That was a jarring sight, but the location makes sense. Corwin explained that this site was the largest available open space in the Bay Area and was perfect for building and testing Makani’s prototypes.

The old Alameda Naval Air Station control tower, repurposed for the 21st century (Photo credit: Jonathan Koomey)

Artillery! (Photo credit: Jonathan Koomey)

Others had told me about Makani’s technology, and the words “kite” and “high altitude” always come up, but these terms are misleading. When I think of kites, I think of Ben Franklin flying the traditional diamond-shaped kite with a tail. The Makani turbine is a carbon fiber wing with propellers (see photo), which Ben Franklin wouldn’t have known what to do with.

Photo credit: Jonathan Koomey

And the words “high altitude” made me think of kites flying in the path of airplanes at 10,000 feet, which isn’t at all right. Makani’s turbines fly at about 300 m (roughly 1000 feet) above the ground.

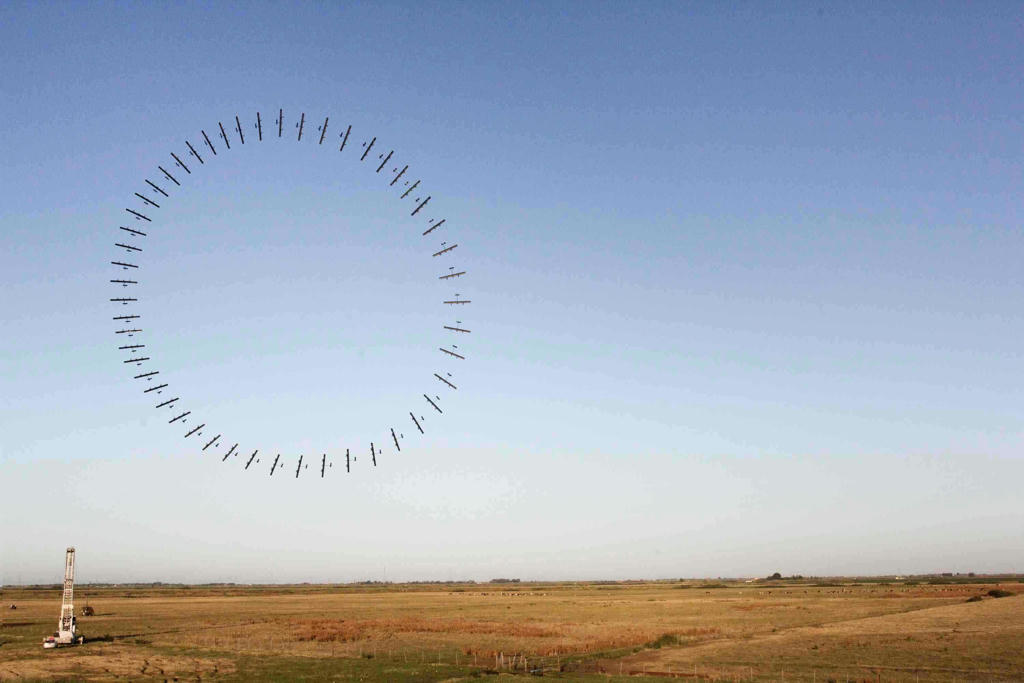

Instead, imagine building and operating just the most important part of the wind turbine, the outer part of the turbine blade (which generates most of the power) without the rest of the supporting structure. In essence, that’s what Makani’s tethered flying wing is—the end of a turbine blade that flies in a circle and generates power. The initial prototype generates 20 kW— the next version should generate 600 kW, assuming they get the money to build it.

Time lapse photo of Makani’s tethered wing flying in a circle (Photo credit: Makani Power)

The wing itself (without the generators and propellers) is incredibly light—I could easily pick it up with both hands, even though it’s about 20 feet long. That’s the beauty of carbon fiber. Super strong, without much weight for the wing itself.

The wing has four propellers mounted perpendicular to plane of the wing. Each is attached to a generator that can reverse itself to serve as a motor. This capability is needed because the wing starts from a cradle on the ground and lifts itself off to achieve the needed altitude, then switches to generator mode once the wing starts its normal circular path. If the wing needs to come down for maintenance, the process works in reverse (and the wing can go from normal flight to sitting in its cradle in less than 5 minutes, which means that it can safely avoid adverse conditions on the ground.

The full wing in flight here showing the four generators/ propellers (Photo credit: Makani Power)

Complex computer control technology is critical to the wing’s functioning. My friend Saul Griffith, one of the cofounders of Makani, told me that the control technology was similar in complexity to that found in missile guidance systems. It’s sophisticated enough to keep the wing on a path with meter level precision, and that’s awfully good.

Power is sent down the tethers. Better to move electrons than to worry about mechanical parts in such a complex environment.

Because the wing flies at higher altitudes than a typical wind turbine, and because it can operate at lower wind speeds, the capacity factor for a Makani turbine will be more like 50-60% (instead of 30-40% for new traditional wind turbines in good sites). And with capital costs typically half of a traditional turbine, the Makani technology should have a significant economic advantage over traditional wind power plants (and competing fossil technologies).

Makani’s technology is yet another example of what I call substituting smarts for parts. It’s a form of dematerialization that allows us to do more clever things using substantially fewer materials but with better performance than traditional efforts.

Makani’s technology is also a beautiful case study of the power of whole system design. Focusing on incremental changes in the design of traditional turbines can yield cost reductions, and we’ve seen that occur since the 1970s (with recent increases in the cost per kW attributable to scaling up to larger turbines with higher capacity factors, among other things). But to create game changing innovation, it takes a comprehensive rethinking of the problem starting with a clean sheet redesign, and that’s exactly what Makani’s innovations represent.

I started out as a skeptic about this technology, but my visit, and conversations with Saul and others convinced me that it holds the real promise of revolutionizing the production of electricity from the wind. My friend Gil Masters, emeritus professor at Stanford and one of the giants in the renewable energy world, wholeheartedly agrees (we just had lunch this week). The trick now, says Corwin, is to raise the funds to create the 600 kW prototype and show that it works.

And that means real money (like $20M). Any billionaires with vision out there who want to move the electric power industry to use significantly more renewable power? Funding further development of the Makani turbine would be a great place to start.